Top Down Construction

Top Down Construction

Using Top Down Construction construction activities can expedite and the project duration can reduce. No scaffoldings, form works not required and the compacted earth can use for the same.

Sequence for Top Down Construction:

Diaphragm wall Installed in both side up to design depth with coupler bars/dowel bars for different level slabs as per alignment.if span is more between diaphragm wall Barrete Piles can be use as a internediate Columns to support the slabs.

The soil is excavated just below roof slab level with margin for P.C.C. thickness, if roof slab level is more than 3 meter and span is more than structural strut to be provided to support diaphragm wall as per design.

Area to be well compacted and P.C.C to be laid(Thk 50 MM), the top of P.C.C. should bottom of Slab. PVC sheet to be laid on PCC surface and over than 3 mm ply to be nailed with concrete surface of P.C.C., joints between Ply to be sealed with PVC Tape.so ply, PVC sheet will act as a separator between R.C.C. Slabs and P.C.C. surface.

Coupler bars/ Dowel bars to be exposed from Diaphragm wall both end reinforcement to be completed as per design.

R.C.C. slab to be cast with suitable size openings for further Construction in suitable interval (around 40 t0 50 mtr) suit to site and for proper air ventilation.

Coupler bars/Dowels bars provisions to be kept for centre wall (In Tunnel case) and opening closing after construction. 100 mm pipe (1 meter C/C)opening to be kept in roof slab thickness for concreting of center wall.

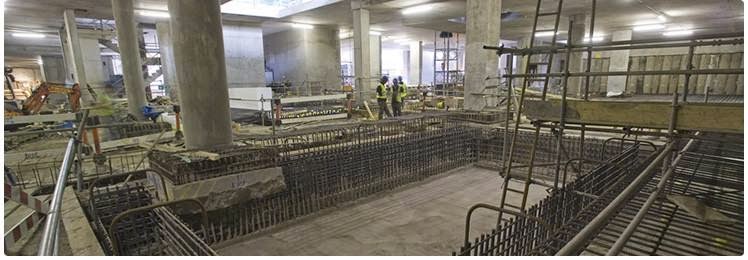

After Casting of slab, excavation to be continued through opening provided with the help of Long arm excavators/Crane and Bucket.

Small excavator to be lowered inside to feed soils for long arm excavator.(Proper Lighting, Air Circulation is must).

P.C.C. to be break by using small excavator and excavation to be continued till base slab level.

Coupler bars to be exposed and base slab to be cast as per design.

Center wall to be cast with dowel bars from Base slab and finally connect with coupler bars from roof slab.

Scaffolding and bottom form work to be fixed below openings , coupler bars to be exposed and reinforcement for opening to be completed and concreting to be done.

After concreting of openings , water proofing if required to be done than backfilling to be done in layers and finally surface to be leveled and reinstating the same

No comments

Post a Comment